Product Range

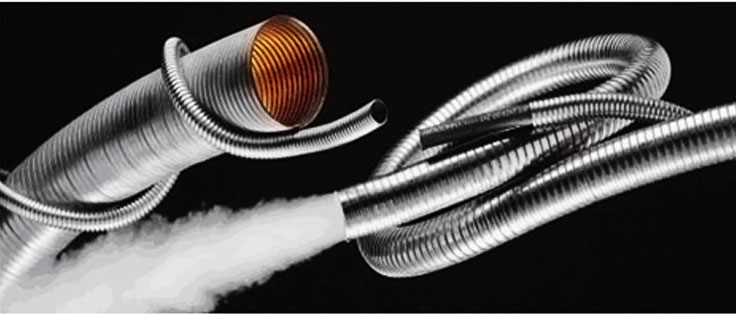

Stripwound Interlock Metal Hose Types

Stripwound interlocked metal hoses are made for a variety of specialized industrial applications and are available in a wide range of metals, styles and sizes. Interlocked hose is manufactured by helically winding preformed metal strip over a sizing mandrel and folding together to form a hose that flexes by the sliding action within the two profiled lock sections. A packing material may be inserted into the profiled locksection within the interlock to make the hose pressure tight or to minimize leakage.

Types Of Stripwound Interlock Metal Hoses:

Double Interlock

The strip is formed with legs that interlock to form a hose that is flexible and ideally suited for conveying dry bulk materials, gas exhaust, or used as a protective cover.

Smooth Bore Interlock

The strip is formed with legs that interlock to form a hose that is flexible and ideally suited for conveying dry bulk materials, gas exhaust, or used as a protective cover.

Packed Interlock Hose

Designed to reduce damage to delicate materials, another steel strip is added inside a hose to provide a smooth interior surface. Smoothbore hose is also flexible and used for dry bulk conveying palletized plastics, grain, coal dust, slag and other dry granular or abrasive materials.

Interlock (Loose Type)

Designed to reduce damage to delicate materials, another steel strip is added inside a hose to provide a smooth interior surface. Smoothbore hose is also flexible and used for dry bulk conveying palletized plastics, grain, coal dust, slag and other dry granular or abrasive materials.

SQUARE OR SINGLE LOCK FLEXIBLE CONDUIT

Designed to reduce damage to delicate materials, another steel strip is added inside a hose to provide a smooth interior surface. Smoothbore hose is also flexible and used for dry bulk conveying palletized plastics, grain, coal dust, slag and other dry granular or abrasive materials.