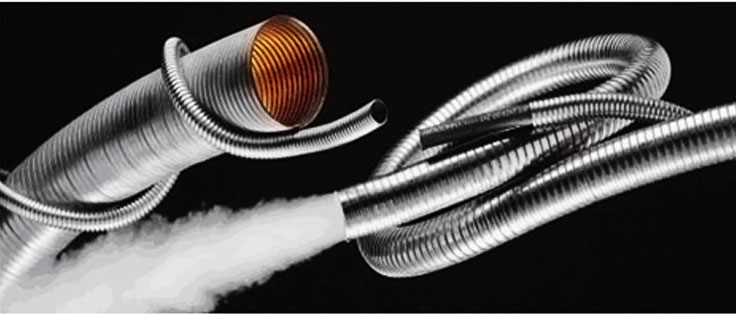

Smooth Bore Interlock Hose

Description:

The smooth bore interlock hose features interlocking construction with inside metal strip lining. The lining provides the smoothness and minimize the impact with reduced turbulence. This will further helps in the free flowing of materials while conveying. The hose has packing in the interlocks that helps in the reduction in air loss while low pressure requirements.

Specifications:

As fabricated in two portions using two separate pieces of metal, the inner diameter of hose is 1” to 8” . The hose supports uni-directional flow of material with specified inlet and outlet connections.

End Fittings:

The end fittings available for conveyor hoses includes: " Plain " Threaded or grooved nipples " Pipe ends " Plate flanges(either rigid or floating) " Quick disconnect couplings

Technical Specification :

PFSB INTERLOCK INTERLOCK SMOOTH BORE CONVEYING HOSE:

| DN | Inside diameter | Outside diameter | Permissible Tolerance | Minimum Bending radiusTolerance: +_10% |

| mm | mm | mm | mm | |

| 20 | 20 | 24.0 | ± 0.3 | 100 |

| 25 | 25 | 29.5 | ± 0.3 | 110 |

| 30 | 30 | 34.5 | ±0.4 | 120 |

| 32 | 32 | 36.5 | ± 0.4 | 130 |

| 35 | 35 | 40.0 | ± 0.4 | 140 |

| 38 | 38 | 43.0 | ± 0.4 | 160 |

| 40 | 40 | 45.0 | ± 0.4 | 170 |

| 45 | 45 | 50.0 | ± 0.4 | 180 |

| 50 | 50 | 56.0 | ± 0.5 | 200 |

| 54 | 54 | 60.0 | ± 0.5 | 220 |

| 60 | 60 | 66.5 | ± 0.6 | 230 |

| 65 | 65 | 72.0 | ± 0.7 | 245 |

| 70 | 70 | 77.0 | ± 0.7 | 260 |

| 75 | 75 | 82.0 | ± 0.7 | 275 |

| 80 | 80 | 87.0 | ± 0.7 | 290 |

| 90 | 90 | 97.0 | ± 0.7 | 345 |

| 100 | 100 | 108.0 | ± 0.8 | 380 |

| 110 | 110 | 118.0 | ± 0.8 | 410 |

| 125 | 125 | 133.0 | ± 0.9 | 470 |

| 130 | 130 | 138.0 | ± 0.9 | 490 |

| 150 | 150 | 158.0 | ± 0.9 | 545 |

| 165 | 165 | 173.0 | ± 0.9 | 565 |

| 175 | 175 | 183.0 | ± 0.9 | 580 |

| 200 | 200 | 208.0 | ± 1.0 | 675 |

| 225 | 225 | 233.0 | ± 1.0 | 765 |

| 250 | 250 | 259.0 | ± 1.0 | 885 |

| 275 | 275 | 283.0 | ± 1.0 | 975 |

| 300 | 300 | 309.0 | ± 1.5 | 1130 |

Applications:

These hoses are excellent for applications involving:

" The pneumatic transmission of flake or palatalized plastics, grain, coal dust, slag and other dry granular or abrasive materials

" The loading or unloading of ships, barges, containers, silos, elevators, highway and rail cars

" For air intake for diesel engines

" Exhausting gases from ovens and furnaces, and boiler draft system & inside liners for stainless steel corrugated hoses & hose assemblies

Features:

" The smooth inner lining reduces the degradation of material and helps in improving the loading and unloading time. " Maximum flow rate is provide for pneumatic conveying applications with directional flow arrows on each length. " Balanced interlocked construction. " Temperature resistant " Corrosion resistant " The stainless or galvanized inner lining helps in providing additional strength and capability to abrasion resistance, which further extends the hose life " The hose can hold its shape and can be easily formed

Maximum service temperature:

" Stainless steel : 7500C

" Galvanized steel : 3500 C

There may be a variation in service temperature depending on the choice

of packaging material, which includes glass fiber yarn, cotton, ceramic

fiber yarn and rubber.